Timber floor structure

When you’re building your wooden tiny house, the floor framing structure is an important part. We already covered the theme of floor in article about different layers and elements of floor frame or various types of flooring, and today we are going to look at cabin floor framing and how to build it.

Timber floor framing construction

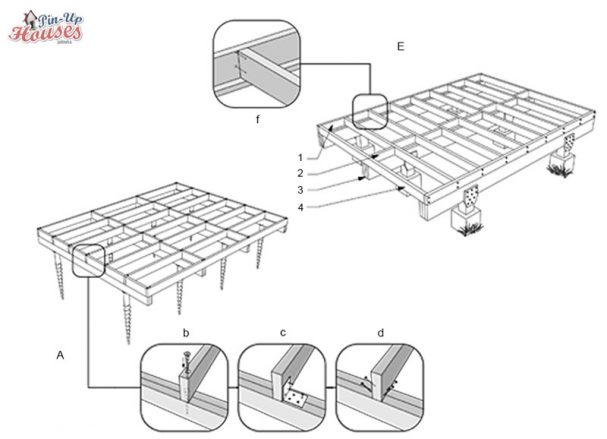

A standard timber floor framing construction consists primarily of floor joists. Placed in repetitive pattern with perpendicular bracing elements in between them, the joists can be connected with metal connectors, through carpentry joints or various different fastening methods. They can be supported either by foundations directly or by floor bearers (beams) laying on foundations and running in direction perpendicular to the joists.

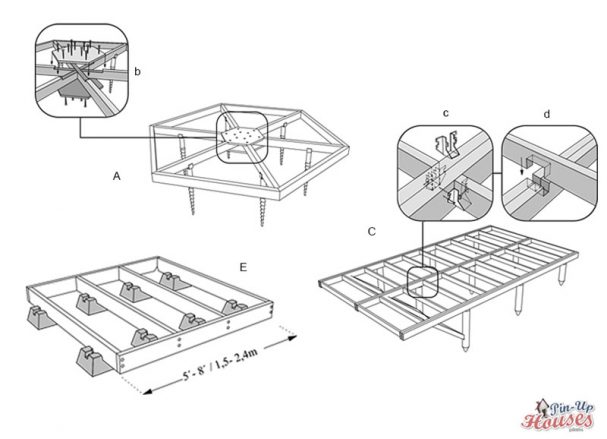

- A. Floor frame with bearers and joists

- b. Screw in an enlarged hole

- c. Metal fastener

- d. Nails on the side

- E. Single level floor frame

- f. Nails or screws

In the first case of the load-bearing components being on a single level, the overall floor height is smaller, which also means reducing the amount of material needed and the costs. On the other hand, the latter option with bearers supporting the floor joists provides better carrying capacities as well as load distribution and also has easier assembly method. In all cases it is important to make sure you understand your small house blueprints correctly and have the right sizes of the elements.

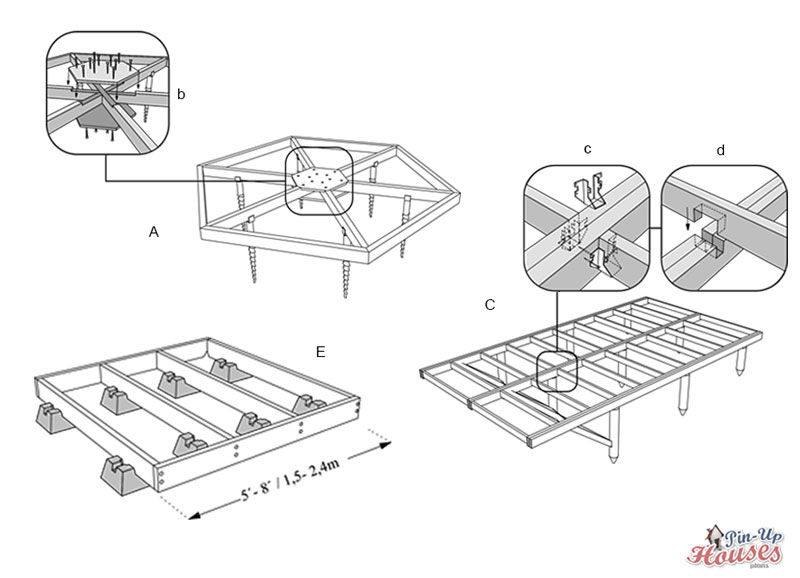

- A. Polygonal gazebo floor frame on ground screws

- b. Board joint

- C. Simple floor frame on pillar foundation

- c. Metal fastener

- d. Carpentry halving joint

- E. Simple floor frame on handi blocks

Regarding the “simpler” approach to tiny house floor framing and the single level frame, it is used for example in structures like tool sheds, kids playhouses, garden decorative mini-structures and other tiny constructions, which do not require a great load-bearing capacity nor a thermal insulation. The floor frames can be shaped into various sizes and designs and quite easily constructed. In terms of foundations, simple ground screws, slab or pillar foundations or handi blocks attached directly to the floor joists will suffice.

Tiny house floor framing bracing

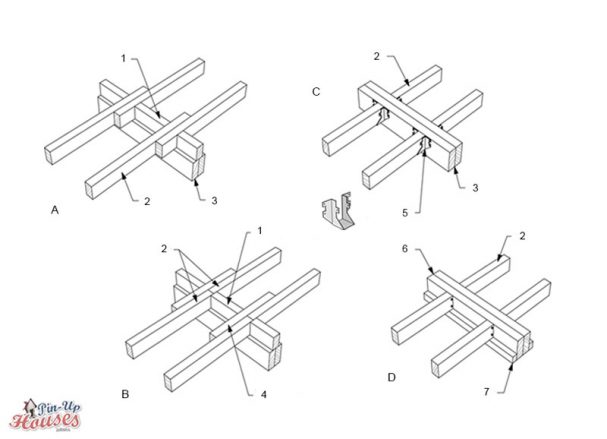

A crucial thing in the timber floor framing construction is so called blocking – a bracing consisting of wooden beams placed perpendicularly between the joists preventing them from tilting, twisting or moving. There are more possibilities of how to place these bracing elements. Around stairs or in other cases when a larger opening is needed, its “boarders” – the joists and bearers on the opening‘s edges need to be doubled for statics reasons.

Timber floor framing construction joists

The installation of the joists and beams for a timber floor structure also offers several options. The two adjusting joists can can be simply nailed together to create one load-bearing piece, so called lapped joist. In spliced joist, a long enough scab (piece of wood) is attached with sufficient number of nails to two joists to hold them together. Metal connectors called joist hangers can hold together joists and beam in cases where the board height is to be reduced by the height of the joists. Similarly, wooden planks running alongside the beams called ledgers can support and hold together the floor joists.

- A. Lapped joist

- B. Spliced joist

- C. Joist hangers

- D. Joists on ladger

- Blocking between joists

- Joists

- Beam

- Scab nailed to side of joists

- Joist hangers

- Built-up beam

- Ledger

Cabin floor framing beams

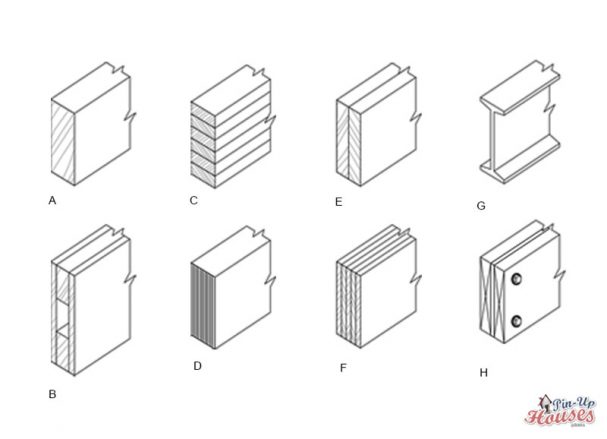

As well as with the other parts of tiny house floor framing, there is more types of floor joists or beams to choose from. As almost in any part of DIY building, you can also enhance the environmental friendly aspect of your small cabin or tiny house and look for recycled beams, which come from demolitions of old buildings, etc. Beginning with the material, apart from the wooden floor beams there are also various composite ones combining materials such as wood, plywood, particle board, laminate, steel and others.

- A. Cut timber beam

- B. Box beam

- C. Adhesively bonded beam

- D. Laminated-veneer lumber beam

- E. Built-up beam

- F. Laminated-strand lumber beam

- G. Steel beam

- H. Flitch beam

Apart from the materials, floor beams also differ in a way how the beam itself is put together. The most common is probably simple cut timber beam. If the two parts of wooden planks are screwed or nailed together, it is called build-up beam, which usually has a width of multiple of 1 ½” / 90 mm. Box beam consists of 2 x 4” / 50 x 100 mm profiles glued and nailed between two plywood boards, while laminated-strand lumber beam is a factory made beam with several wood-based boards joined together. Wooden profiles glued together, with more options of final finish, create adhesively bonded beam. For large spans or requirement of high load-bearing capacity, steel beam is the best choice. Steel is also used in flitch beam, where a steel band is fixed between two wooden profiles, which also increases their strength and load-bearing capacity. A laminated-veneer lumber beam prepared by laminating veneer layers is also quite popular choice.

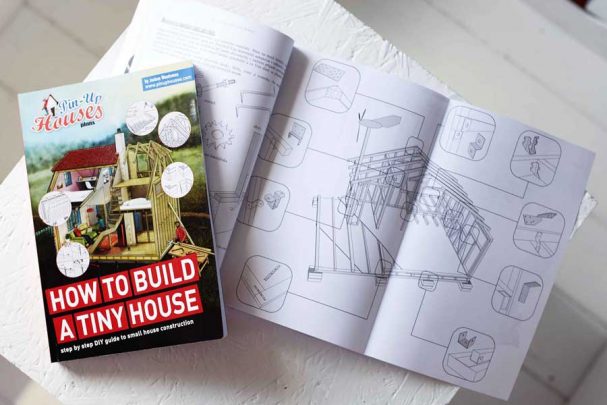

Floor framing and how to build a tiny house

So you learnt something new about cabin floor framing? Or you still feel uncertain? We have a solution for you! In our illustrated step by step guide How to build a tiny house you will find all not only about timber floor framing construction, but also other parts of DIY building and small wooden house plans. When is building permit not required? Full of useful information, detailed manuals, illustrations and photographs, our guide is available to order in printed version or as an electronic book right here.