On top of it all…

There are diverse types of roofs. We have already discussed the roof types and so we know that there are gable roofs, like the one Diana has, there are shed roofs, like the one our most favourite, Marlene, has or gambrel roofs, like Sofia has, as well as many more… In this article, we will have a look at roof covering materials that you can use to build your own dream house.

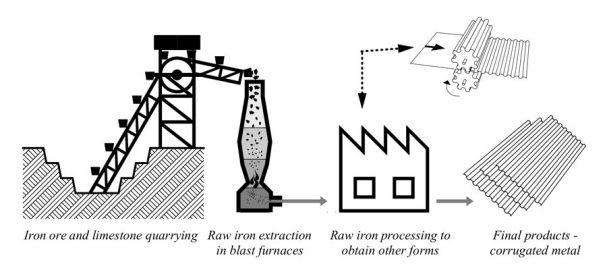

Know what it’s made of

There are several types of material that are used to build roofs. You can use metal, asphalt, wooden shingles or even clay. You can even turn your roof into a garden and grow some greens on it (see here). The choice is up to you. You pick your favourite. Each material has its pros and cons. Each roof needs a certain type of maintenance, each has their own degree of sustainability.

HEAVY METAAAAAAAL!!!!!!!

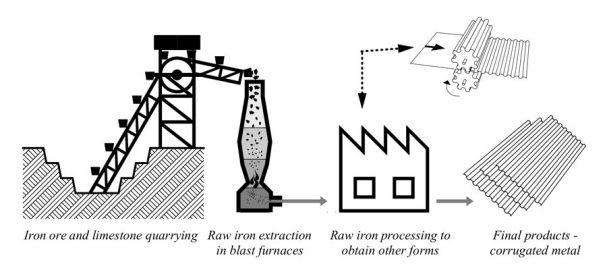

ROCK ON! LIVE LARGE, ROCK HARD… yeah, it’s time to crank it up! There are several types of metal. There is industrial, there’s gothic, death metal, and then there is sheet metal. That’s the one you’re looking for. You can build the city on rock and roll, but your DIY roof needs to be solid! There are varied forms of sheet metal, headed by the most common representative – corrugated metal. These are the obvious winners in the competition for the most often used roof and wall covers on the planet. It’s no surprise, then, that they come at a relatively good price and are the most readily available.

Right! Metal is my life!

Right! Metal is my life!

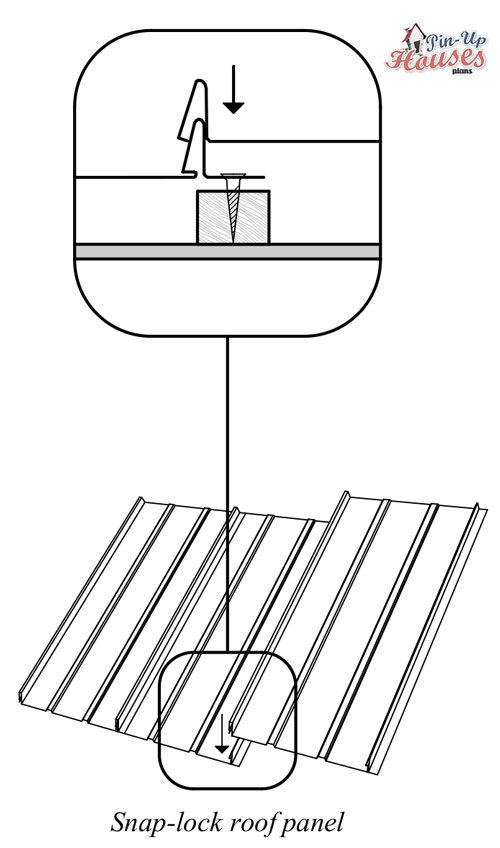

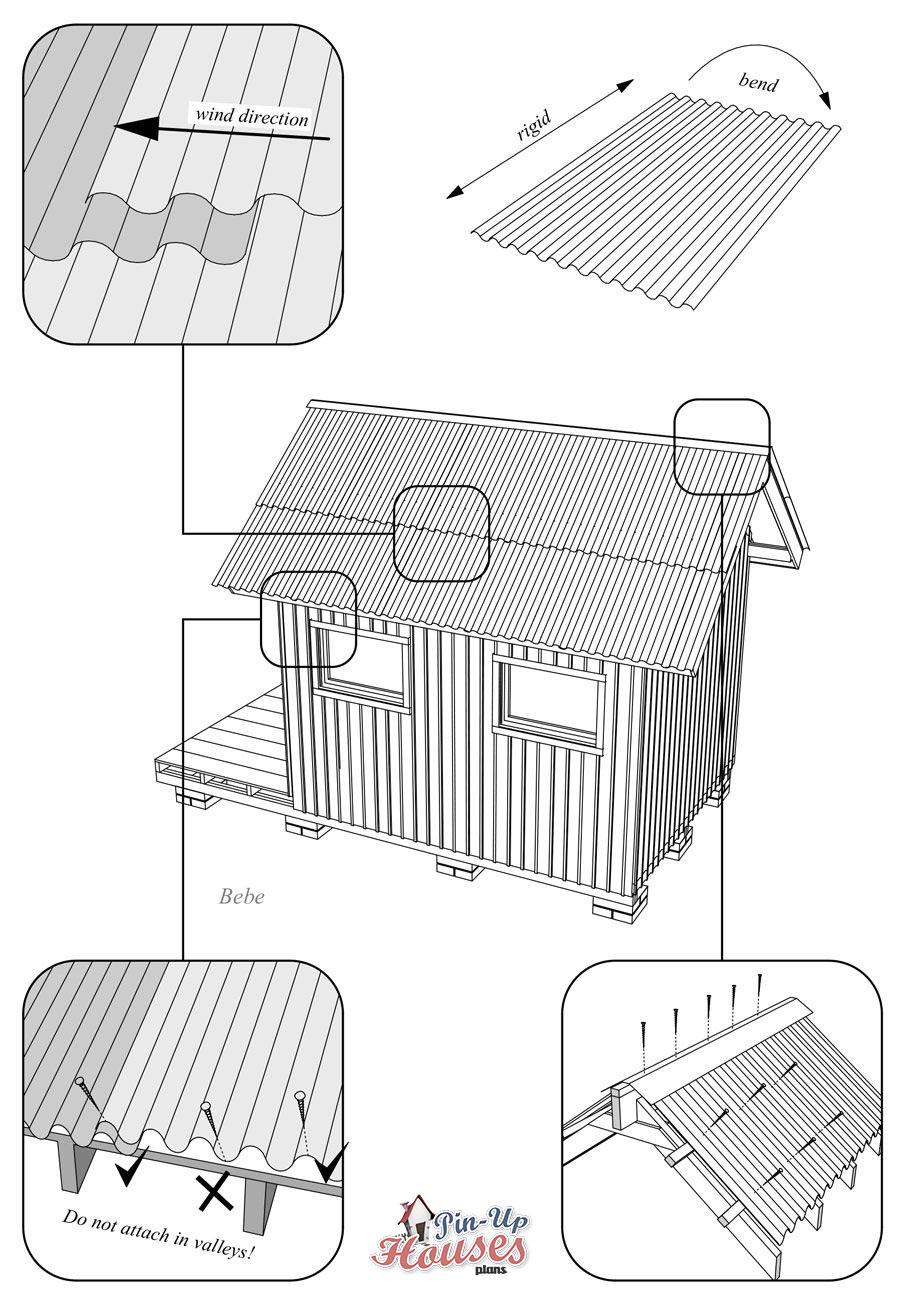

Now that you have your sufficiently heavy material to build upon, you need to make sure that when you lay your corrugated sheets on roof, all the winds fit into each other, forming one huge sheet.

Here is a picture of BEBE, the scheme shows sheet METAL roof with corrugation.

Yeah! It’s pretty heavy!

WATCHOUT!

There are several precautions you need to make sure you take:

There are several precautions you need to make sure you take:

First, you need to make sure that you do not attach the roof in valleys, like you can see on this picture below:

Second, you should form a proper supporting structure below the metal plating, as you can see in this picture below:

Second, you should form a proper supporting structure below the metal plating, as you can see in this picture below:

Also, make sure that when you attach the roof to the wooden supporting structure, you do that only on proper places. Ideally, the metal plating should be joined together and fixed with screws only on spots where it is supported by the wooden structure, as illustrated in the picture above.

Third, RIDGEBACK! No worries, you do not need to get yourself a gigantic dog. But you need to make sure that your roof has ridge gap. This protects the roof from leakage. During heavy rains, the rain may fall too hard and this sometimes results in extra leakage and you don’t want that, obviously, so make sure you equip the tip of the roof with ridge gap, as shown below:

Pff! Corrugation ain’t my style!

Corrugation not your style? No problem! There are several other types of metal to satisfy your lust for heavy stuff, you metalheads! There’s flat metal, PBR-panels, snap-lock roof panels… you choose

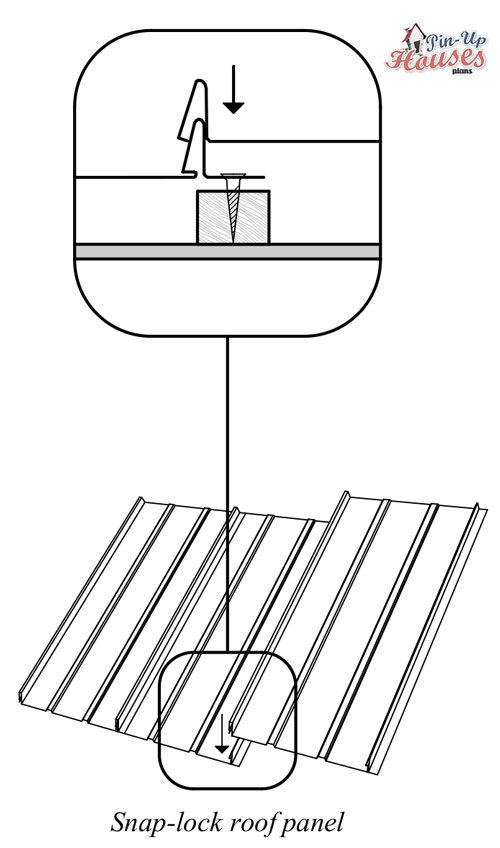

Snap-lock roof panels

Are probably the second most suitable. They are panels of profiled sheet metal intended specifically for DIY metal roofing or façade panelling. Here again, as in corrugated plates, you need to give special attention to the connections. With the snap lock, however, as its name suggests, the plates will fit one to each other with lock and they may stay together slightly better than the corrugated panels.

Yeah! That’s the way to do it! HEAVY METAAAAL!

If you really want to learn to rock your head out, check out our instruction materials: HOW TO BUILD A TINY HOUSE, by your fellow metalhead – JOSHUA WOODSMAN. Don’t get fooled by the name. Wood gave us guitar, and guitar gave us rock’n’roll and rock’n’roll gave us pinup houses. Simple as that! Build your own dream house today with this rockin’ book! ROCK ON BEBE! HELL YEAH!