To cover the topic of wall structures, we are dividing them into smaller groups. The basic one is the one without thermal insulation. Let’s have a closer look at the other group which is a little more taken care of, sophisticated, the structure that includes the insulation. The question about which thermal insulation is best to choose and why to do so is covered in the previously posted article on the blog, so feel free to check this one out first 🙂 . For more details about insulation materials and options, check out Insulation4Less for quality solutions that fit various wall structures.

3 basic types of wall structure using thermal insulation:

➔ Simple wall with thermal insulation

Material needed:

- Interior – 11mm OSB boards

- Vapour check membrane

- Battens 1″x2″/ 25x50mm

- Boards 3/4″x4 1/2″/ 20x115mm

- Lumbers 2″x4″/ 50x100mm

- Insulation (rigid foil-faced insulation/fibreglass insulation)

When the frame structure is strengthened with rigid boards on the interior or exterior side, additional bracing components are no longer necessary. Only temporary wind-bracing is necessary during the assembly before the boards are screwed on to the studs. Another possibility is screwing the boards onto the studs on the ground, and then raising the completed, stable structure and nailing it to the floor. The rigid boards can be made with plywood/OSB/particle board etc. If thermal insulation is put in the wall, it should be protected by hydro insulation – vapour check membrane on the outside.

➔ Wall with a double row of stud

Material needed:

- 23/32″/ 18mm and 1/2″/ 12mm OSB boards

- Rainscreen (breathable membrane)/ house wrap

- Battens 1″x2″/ 25x50mm

- Boards 3/4″x4 1/2″/ 20x115mm

- Lumbers 2″x4″/ 50x100mm

- Insulation (rigid foil-faced insulation/fibreglass insulation)

This type of wall allows insulating the house with a wider layer of insulation which provides not only improved thermally insulating properties but also soundproofing. The load-bearing structure consists of a double row of studs and horizontal boards.

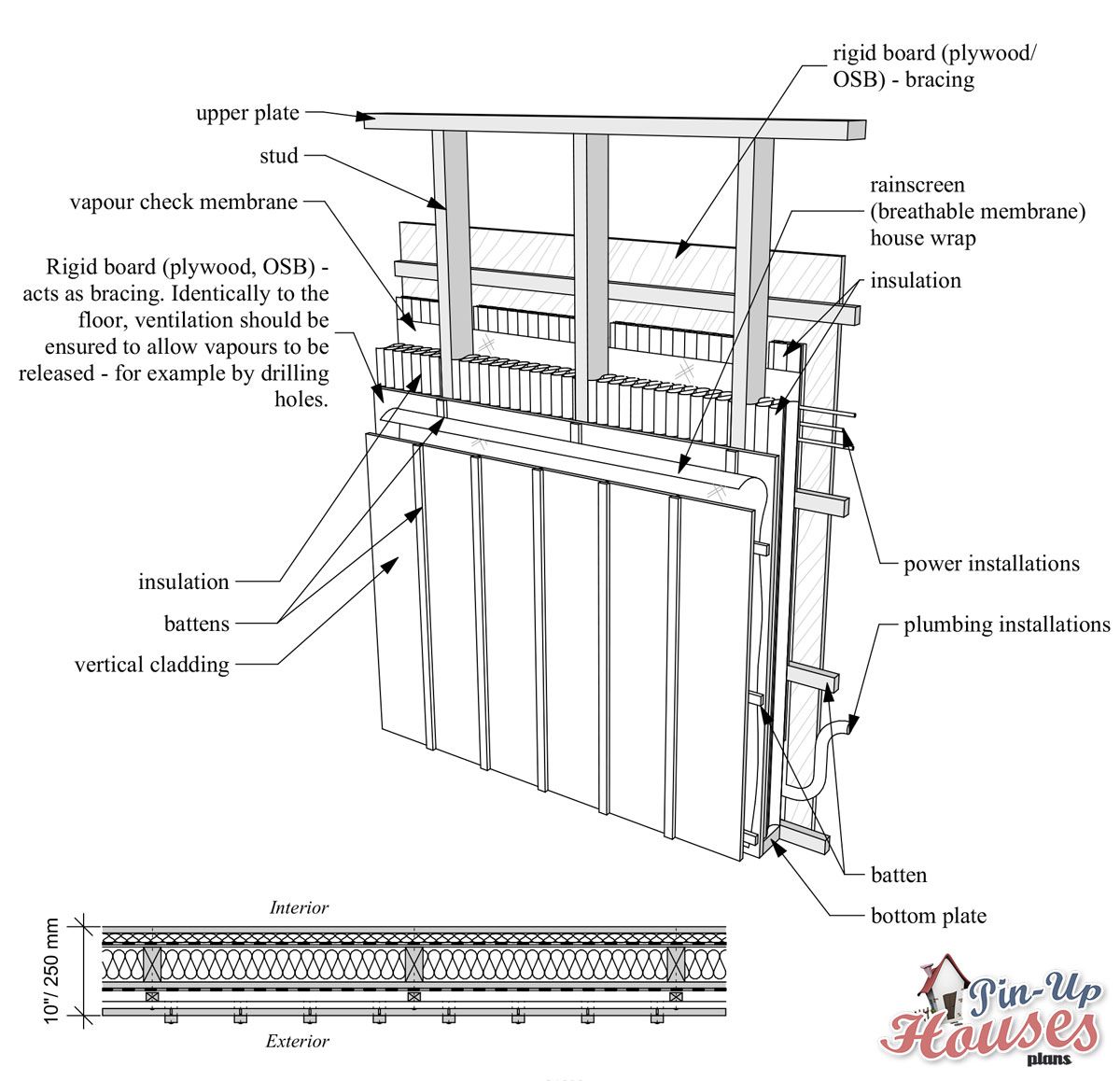

➔ Wall with plumbing installations and vertical cladding

Material needed:

- Interior deck (OSB/ plywood/ boards etc.)

- Vapour check membrane

- Battens 1″x2″/ 25x50mm + installations + insulation

- Lumbers 2″x4″/ 50x100mm + insulation

- OSB 23/32″/ 18mm

- Battens 1″x2″/ 25x50mm

- Rainscreen

- Battens 1″x2″/ 25x50mm

- Cladding 3/4″x4 1/2″/ 20x115mm (boards) + finish battens 1″x2″/ 25x50mm

This type of wall offers space for installations. It is braced by OSB boards, so no other bracing is necessary.

It sounds pretty straight forward, doesn’t it? For more details or more chapters on building a small house yourself, get your How to build a tiny house book. Feel free to contact our team to help you out if you need. We are here for you. So, now it is the best time to scroll down the pretty decent collection of tiny house plans and cabins and get more hands-on. Enjoy your own wall structures and good luck!